Richard’s 2mm track building and baseboards

Richard Wilson

14th June 2020

3 minutes

Richard has started work on his latest 2mm Finescale home layout. He’s started with track and baseboards, with an innovative way to align and hold the boards together.

The Trackwork

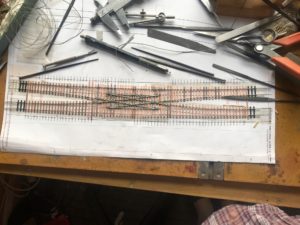

Here’s where the track building starts, laying out some point work – quite a fun scissors crossover- and on a curve too.

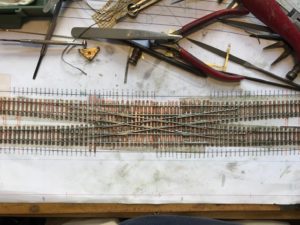

Double crossover is making distinct progress. Wing rails and blades to complete, then gapping and rail breaks to do the electrics.

The crossover track work is now complete, apart from cleaning, gapping for electrics and laying in place, wiring, tiebars, baseboard to put it on, painting, operating machine, ballasting, any thing else? So it’s pretty much complete then!!!!

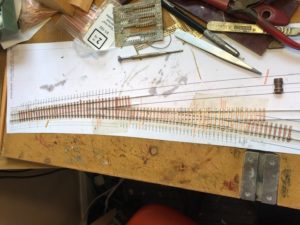

The north end pointwork is taking shape,

With these are done it’s all plain track…

Once you have the points, they need to be operated from underneath in a reliable but hopefully none visually impactful way. Here’s his version made from silver soldering brass sections together, and then machining, and they end up under the tie bar like this.

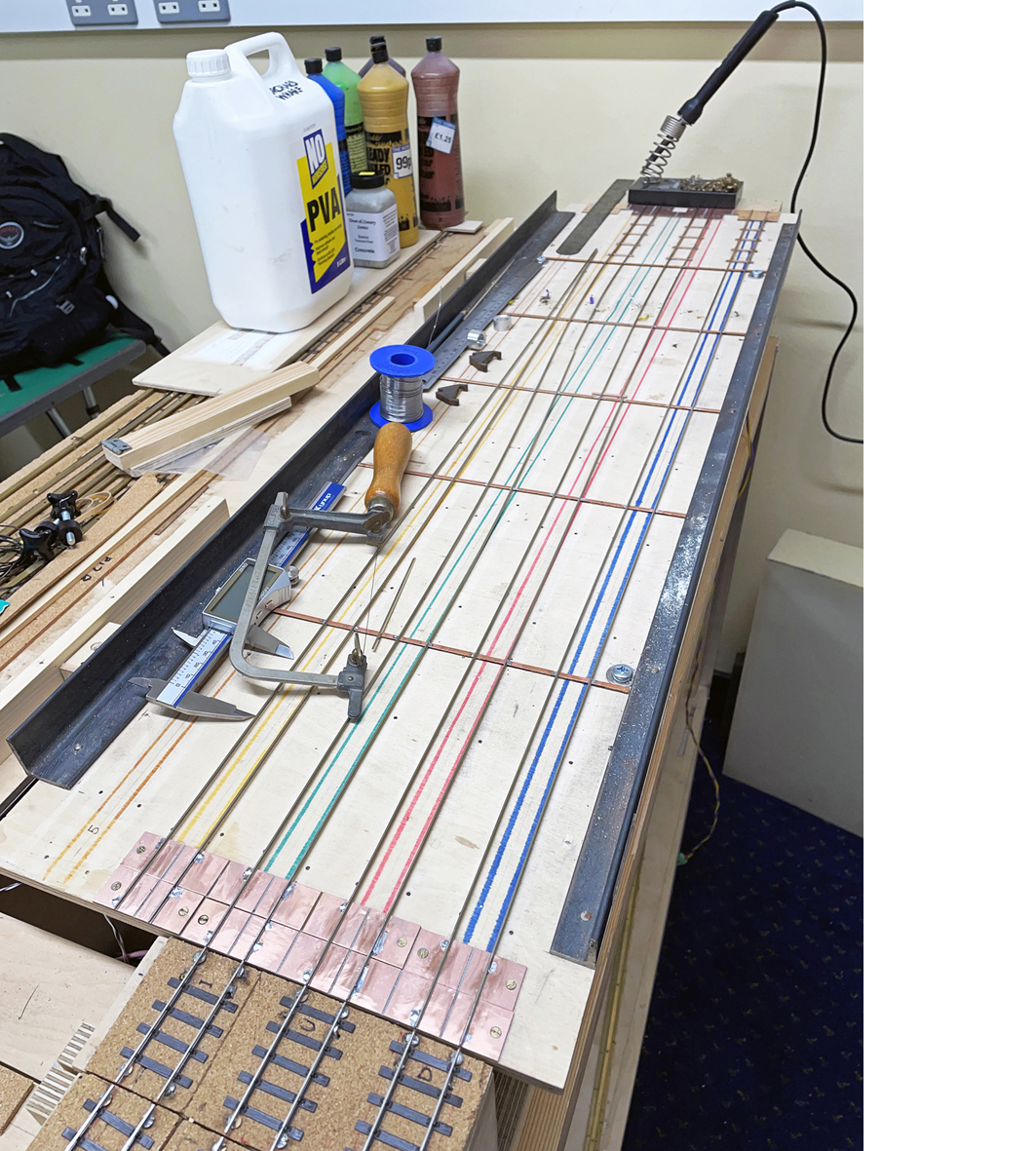

Baseboards

Baseboards have now been erected, in principal. These are PAC aluminium frames with a 6mm ply top. I probably need to make a new one as the ply I had in stock was a little warped- probably best to get a new piece now rather than regret it later. Templot plan, and a wagon for scaling (2m long and 350 mm minimum width. There is enough to cut the baseboard at the rear to a curve for the back scene- but that’s for later.

The baseboard frames are the work of PAC. And worthy of comment. I don’t think they were ever written up. Essentially 3×1 aluminium channels are bolted together using angle sections at the corners. The ends are milled to accept the long pieces so as to present the flat side to the outside world. Dowel pins are fitted to jig drilled holes in all the end channels. On the male channel a loose fitting 15mm pin cross drilled is fitted. It is loose in its fitting to have some flex. You can see this in the picture of the end plate. The female end is an aluminium block which has a hole to accept the pin. The block is cross drilled through the hole and tapped.

The block is firmly fitted to the rear of the channel. To join the boards a tapered bolt is inserted from the side, this passes through the cross drilled holes in the male pin, and female block. It has the same tread as the female block and the taper draws the boards firmly together. It is utterly ingenious. Mike Randall has the template for drilling the holes in the end plates I believe, but not beyond the wit of man to make new ones. The same principles could work for timber baseboards. No more bolts.

Richard is one of the members of the Copenhagen Fields team. Look through the rest of our blogs for other modelling techniques, including track building in EM, laying track in OO, and baseboard building and find out how to join us here

Thursday Track Nights

We are open on Thursday evenings from 7pm to 9pm at our Keen House clubrooms. Visitors are welcome, please come along and introduce yourself.

Address:

Keen House, 4 Calshot Street, London, N1 9DA

Become a member